One of my CNC Dude YouTube viewers was having some kind of a duel with a Jedi and broke his Master Replicas Darth Maul Dual Lightsaber coupler. He asked if I could be commissioned to build this part and although many people have asked whether I am willing to build parts for a price, the unfortunate truth is that I lack the time to undertake pretty much any project I can dream on. What I thought I could do, however (and since I happen to be the proud owner of one of these replicas), was draw the coupler in my CAD tool and provide him with a drawing he could then use to commission some machine shop time (maybe a local Maker Space???).

I am going to say the drawing came up almost perfect, except for the thread which is a little bit past my level of expertise. Had I been a mechanical engineer, this would have been an embarrassing fact to admit to, but as an electric engineer I have to say I am blown away by the fact that I actually draw the darned thing! I imagine any knowledgeable machine shop guru should be able to do the thread correctly. So be aware if you download the files for this project, that I am not certifying the thread to be correct. If I happen to know how to fix it, I will most likely update this posting and advise accordingly.

Now, here are a few points which I want to add to this report. As I searched on the web (mostly forums), it became apparent that this part brakes a lot. As I was analyzing the part in my hands, I came to the conclusion the cylinder in question is the product of a casting procedure. I am not certain of the material (aluminum, zinc?), although I think it is aluminum. What I can tell you with 99% certainty is that it wasn’t machined. For example, the coupler I was taking measurements from is not perfectly round (you can only notice this by measuring with a caliper, not by touching it). Whereas flaws of this nature make perfect sense as them being artifacts from the cooling process, there is no way I can envision them as being the product of a turning operation. But to be honest, it is pretty obvious it is a casting by just looking at it.

Will an actually machined part come out to be stronger? That is a question for which I would love to have a good answer…

On my search, I also saw that at some point in time you could have bought this part for $20. I am going to tell you something! If you can find this part either on eBay or one of those lightsaber depots for $20, feel free to rip it without even thinking twice about it as I can assure you there is no way you will be able to get this part manufactured in the once or twice quantities for $20. Maybe $50-$100 if you are lucky? So my advice is to find a machinist friend and let them make the part just for the fun of it. Heck! That is what a hobby is all about!

One last important detail. The model I am about to show (and the one for which I am providing drawings) is for a solid as opposed to the real thing which is made of two parts bolted together with an 8×1.25 mm socket screw. If you were to machine this, I don’t see why you would want to make it in two parts (unless of course you want to recreate the scene where Obi Wan chops off the unit with a single blow…) Feel free to get creative and decide how you want to make this into two parts, but if you have these lightsabers then you already know.

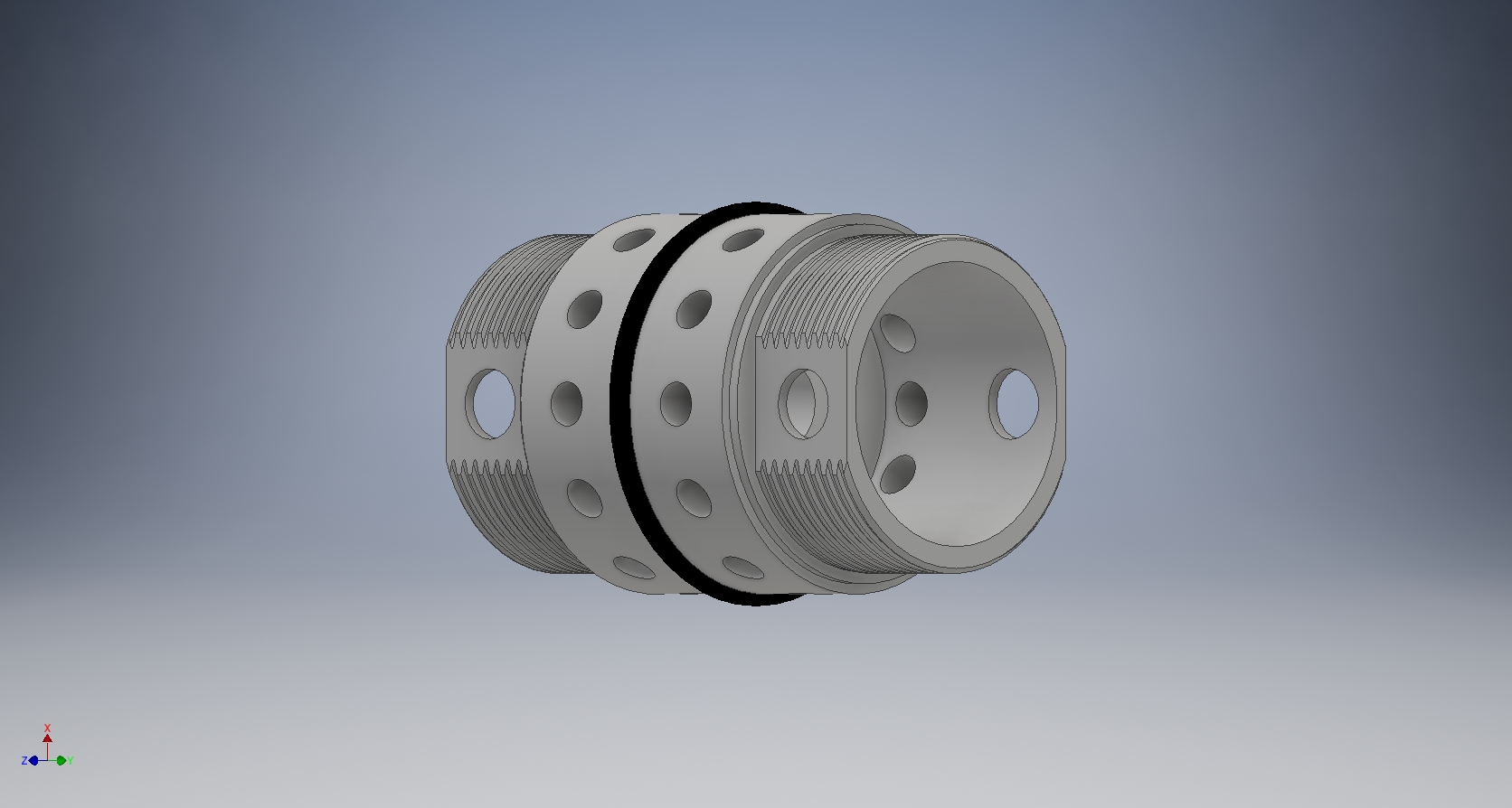

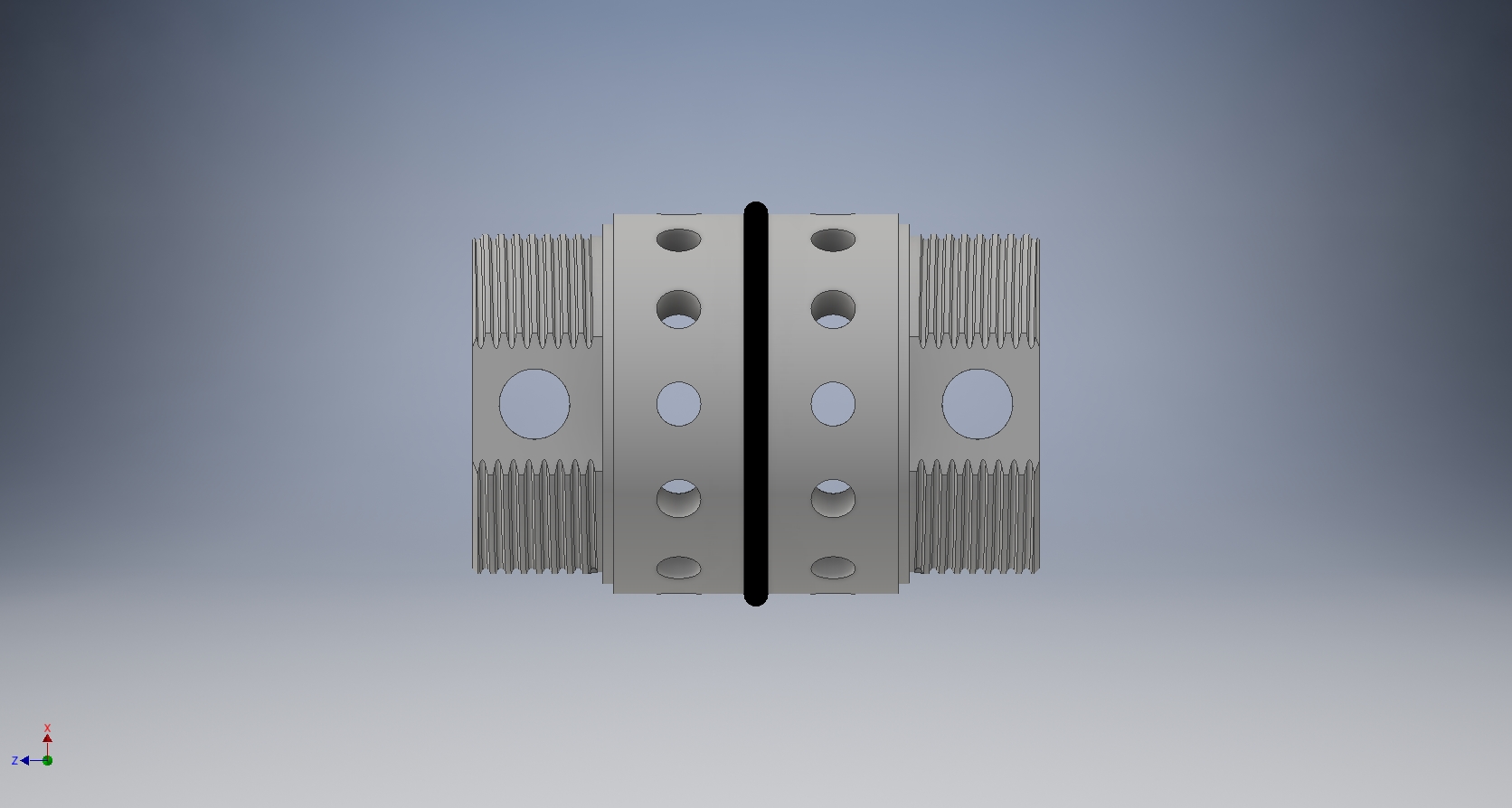

And without further ado, this is what the model looks like:

You can download a drawing with the measurements and some notes here: (WARNING!!!! THE THREAD IS NOT ACCURATE!!!) Darth Maul Coupler Drawing PDF